|

Cushcraft R5 ˝ λ Vertical |

Maintenance and Repair |

|

CUSHCRAFT R5 (10/12/15/17/20 m)

Cushcraft have

made many vertical antennas; R4, R5, R6, R6000, R7, R7000, R8 etc. All

are ˝ wave radiators with 4 or shorter base-load rods. Those "radials"

are in fact a top hat capacitance. The quality of the R6 successors

decreased, see Product Reviews on www.eham.com.

The 17ft half wave vertical is covering the 10,

12, 15, 17, and 20m amateur bands. The antenna does not require

traditional ground radials, so no need for unsightly radials and is so

light a normal scaffold pole would be ideal to mount the antenna.

POWER

The

manual states that this shortened half wave radiator is suited for 1.8

kW pep power and that is remarkable for this type of 5 m-tall antenna.

The vertical passed a test with a borrowed 1.5 kW amplifier with no-ill

effect. There were no signs of failure on the traps or matching unit. |

R5 a 5 band vertical on top of a 12 m mast. |

PRACTICAL TESTS

The R5 is

mounted on a 12 m mast. My 2 el. Yagi only outperforms this antenna if

the beam is pointed to the station. The difference is very noticeable in

SSB/CW DX pile-ups, but if I can hear them I can work them. It provides

useful DX performance. I did comparisons with my open wire fed inverted

V W3DZZ and on 20 m: R5 = W3DZZ at 1500 km. On all bands beyond 1500 km

the signal strength is about 1 S unit better than the W3DZZ.

This antenna is very usable and, being asymmetrically

fed, with no radials and only 4 × 1.24 m stainless steel whips («fig)

is attractive for apartment dwellers. All hardware is aluminium or

stainless steel. The aluminium durability is good but not as good as

Fritzel's tubing. It has withstood many heavy windstorms without a

problem and currently is bent over at about a 10 – 15 degree angle. It

is rugged and not too tall mounting without guy ropes. This antenna is

sensitive to metal objects in near field. Prevent installation over a

metal roof or near out other antennas because they will detune the R5

considerably.

INSULATOR

|

Fig a: A bare weather beaten insulator. |

Fig b: An unprotected new R7 insulator. |

The fibreglass base insulator (fig a) is a

polyester-coated tube. The polyester surface has the tendency to

"evaporate" and the bare glass fibres then are like a sponge attracting

absorbing dirt and moisture.

|

"Bumper" spray

The

insulator was "painted" with layers of 2 component polyester resin and

sprayed (fig») with "bumper spray", a black non-metallic spray paint. It

prevents the deterioration of the polyester. |

Insulator protected with black non-metallic spray paint. |

MATCHING UNIT

L to R: choke balun (brown colour wire) and 1 : 4.84 auto transformer (black and white colour wire).

On several

homepages the transformer is called a 1 : 4 balun. That is contrary to

the print design. On the auto transformer are 5 black turns and 6 white

turns through the toroid. So the transformer step up ratio is 5 : (5 +

6) and that is an 5˛ : 11˛ = 1 : 4.84 impedance ratio. All matching

units' shows equally designed print boards.

I replaced the two 86 pF caps in series with a single transmitting high current 47 pF doorknob type.

This happens if one use the antenna with an ATU and a lot of power on more than the specified 5 bands!

MAINTENANCE

The traps

should be carefully loosened and the contact area and all other

aluminium hardware should be cleaned with Brillo pads (steel wool

impregnated with soap).

COIL

|

Water got inside a trap due to cracked heath shrink tubing.

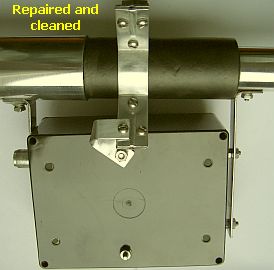

Cleaned and repaired coil |

I have been using my

2ndhand R5 for more than two years and then some problems arose. The SWR

was varying and increased on some bands. I took the antenna down and it

turns out that water got inside a trap because cracked heath shrink

tubing and a split in the joint between the coil former (force-fit?)

into the aluminium tube. The heath shrink tubing was carefully removed

and the coil, covered with "transparent contact adhesive", was cleaned

with thinner.

Once clean, the split should be filled with epoxy

glue (2-part polyurethane adhesive), the coil buttered with transparent

contact adhesive and reassembled with heath shrink tubing. The process

with the transparent adhesive is for preventing that water gets inside

the trap.

Leaking spots are the heath shrinks tubing over the bolt onto the connection of the coil former with the tube.

CAPACITOR

The

capacitors paralleling the sealed coils are coaxial types with a rod, a

tube and a dielectric tubing in between. One end is sealed with heath

shrink tubing and the other end is protected with a cap.

One capacitor failed because of a burst cap and water

get into the coaxial system. This changed the dielectric constant of

the capacitor, thus moving the resonant frequency, and the SWR increased

dramatically. Flash-overs when running high power shorted the wet

capacitor out and evaporated a part of the insulating tubing.

This was replaced with a short piece of PTFE tubing

and all of the components were dried, cleaned and reassembled with

contact cement and heath shrink tubing.

It seems that glue sticks («fig) for a glue gun are suitable for replacement of the insulating tubes.

All caps are replaced with («fig) rugged caps.

|

All R5 parts of the 1989 model. |

Measuring the traps is

only possible by comparison with another R5. Make sure that you do not

touch any part of the antenna and vary the frequency of a (grid) dipper

meter until a strong dip is seen. Move the meter away while retuning

until a very shallow dip is seen. Take note of the trap frequency.

Repeat this process with the repaired R5.

RADIATOR DIMENSIONS

The assembly and installation manuals of 3/1989 and 10/1989 show different dimensions for the radiator.

With

the antenna on a 2 m mast I measured the SWR, on each band with a half

wave (or multiple) 50 Ω cable for that band between the feeder point and

an analyser. I found the dimensions in the schematic by varying the

sections to match the specifications for SWR ~ 1

|

Back on a 12 m mast the R5 performs by ˝ – 1 S unit better (75% of the QSO's) than the inverted V W3DZZ. |

MHz |

14.200 |

18.100 |

21.400 |

24.950 |

29.500 |

|

With a 12.5 m 50 Ω coax cable feeder line the SWR was: |

SWR |

1 |

1 |

1.3 |

1 |

1.1 |

NOTE: 2 TYPES OF TRAPS FOR 15 m and 17 m

|

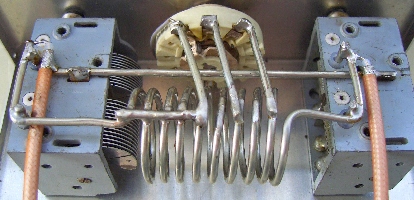

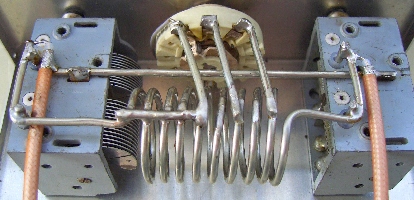

Combined 15/17 m trap March 1989 |

15 + 17 m traps October 1989 |

WOBBLED ANTENNA

The antenna wobbled due

to the gap caused by evaporation of the polyester. The tube was removed,

the inside of the insulator applied with layers of 2 component

polyester resin until a minimum variation of fit. Then I sanded the

insulator for a perfect cylindrically curved shape and applied the last

layer and placed the antenna back in the insulator. In fact the

insulator was restructured to its original diameter.

I used a polyester repair set (for automobile) and

applied the 2 component polyester resin with a brush. Eventually fill

holes with fibreglass. The 2 component polyester resin can be used in

combination with fibreglass mat and fibreglass thin film to fill holes

in surfaces of steel, aluminium, wood, concrete and polyester. Polyester

resin is elastic and resistant to chemicals and weather influences and

is, after hardening only sand smooth mechanically.

Due to the gap the antenna wobbled and one of the straps was broken.

I replaced a shortcut 27 pF cap with 4 × ceramic tube caps in series/parallel.

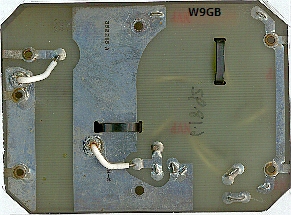

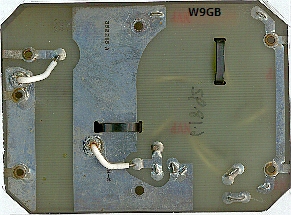

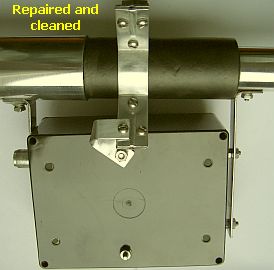

Greg, W9GB found a potential replacement source for damaged MN-7 black enclosures.

http://www.electronicsurplus.com/commerce/catalog/product.jsp?product_id=69167&czuid=1195158651593

He wrote: "I have found the a black plastic case

(fig») that is identical to the MN-7 Matching Network enclosure used by

Cushcraft. It appears that Cushcraft used the Polycase "EP" series, EP-8

model. The POLYCASE® EP-8 size is identical

and injection mouldings from the dies are identical in every detail to

my MN-7 (1992). I do not think Polycase makes the "EP" series currently.

These EP-8 boxes are now surplus NOS from Electronic Surplus, Inc.

(ESI) in Cleveland. OH. ESI had 441 in stock at $ 4.50 USD each -- I

just received 3 to confirm match".

ATU

|

|

|

|

Incidentally, I use an easy to build pi-ATU to always ensure that the transceiver is loaded with a SWR = 1. |